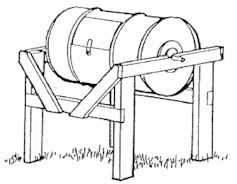

The barrel composter is fast way to make small batches of compost. Mix 1/3 nitrogen materials with 2/3 carbon materials. Turn rotating drum daily and keep materials as damp as a wrung out sponge.

Cost: Less than $100 with new materials, less if using recycled materials

Capacity: 3-4 30-gallon bags of yard materials

Materials:

Lumber

Cut lumber into the following lengths. Use cedar or non-arsenic pressure-treated lumber. Measure and cut the pieces as assembled, to be sure of correct fit.

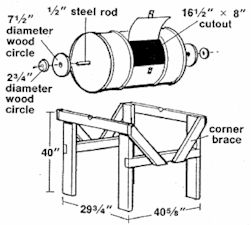

- 4 pieces 2 x 4 x 40" (legs)

- 4 pieces 2 x 4 x 29¾" (frame horizontals)

- 2 pieces 1 x 3 x 40 5/8" (cross braces)

- 4 pieces 1 x 3 x 23¾" (corner braces)

- 2 pieces ¾" x 7½" diameter wood circles (bearings)

- 2 pieces ¾" x 2¾" diameter wood circles (bearings)

Hardware

- 1 55-gallon drum (composter)

- 2 hinges, 1 ½" x 2"

- 1 small hasp

- 1 steel rod, ½" x 40 ½"

- 8 stove bolts, ¼" x 1 ¼ "

- 12 stove bolts, ¼" x 1"

- 28 wood screws, #10 x 1 ½"

- 1 pint black rust-retardant paint

Tools:

- Electric drill

- Screwdriver

- Pliers

- Saws (saber saw with metal-cutting blade and handsaw or circular saw)

- Paintbrush

- Gloves and eye protection

Construction Details:

- Use 55-gallon drum that has not been used for toxic chemicals. (Paint barrels are ideal.)

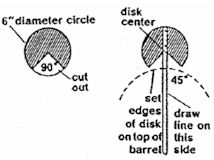

- Drill a ½-inch hole in exact center of each end of drum to accommodate ½-inch steel rod. Make simple gauge to find center by cutting a 6-inchdiameter circle out of heavy cardboard or wood. Mark the exact center of the circle, and cut out a 90-degree wedge. Hold the gauge with cut-out edge against the edge of the drum. Draw a line where the piece of wood bisects end of the drum. Move the gauge 90 degrees, and draw another line. The intersection of these lines will be the exact center.

- Draw lines for opening in barrel, making sure to round corners slightly. Drill a ¼-inch hole somewhere along one of lines, to start saber saw. If barrel has ribs, cut a 1-inch V notch on each rib to facilitate opening door. Attach the hinges and hasp to barrel and lid with ¼ by 1-inch stove bolts.

- From ¾-inch wood, cut two 7½-inch-diameter circles (bearings) and two 2 ¾-inch-diameter circles. Drill a ½-inch hole in center of each, and apply glue to 2 ¾-inch circles. Glue each 2 ¾-inch circle to a 7½"-inch one. (Temporarily slip them over ½-inch steel rod and clamp them.) After glue has dried, remove bearings, insert rod through barrel, and assemble as shown in illustration below. Use four ¼ by 1-inch stove bolts in each bearing to bolt it to drum.

- To build support frame, use a corner lap joint to fasten legs to horizontal pieces. (To make a corner lap joint, remove one-half the thickness of the stock to a length comparable to the width of the stock on the ends of both pierces to be joined.) Use two #10 by 1½-inch wood screws in each joint. Cut grooves (dadoes) on legs 23 inches from bottom to fit 1 by 3-inch cross braces. Cut 45-degree angles at both ends of 23¾-inch-long corner braces, and

attach them across corners, as shown, with #10 by 1½ inch wood screws. Cut a ½-inch notch in center of each top horizontal piece to accommodate rod. - Drill several rows of ¼-inch holes along bottom of barrel underneath door opening, to eliminate excess moisture. Paint barrel unit inside and out with black, rust-retardant paint.

Source: University of Wisconsin–Extension - Solid and Hazardous Waste Education Center

PAY ONLINE

PAY ONLINE